One of the most widespread methods for withdrawing water from the ground, both in the agricultural and home sectors, is to use submersible pumps to create the so-called water lifting system, which in the simplest version consists of the pump, the electrical panel and the delivery pipe that transports the water to the surface.

“The pipes constitute the arteries of the lifting system and their correct choice is of fundamental importance.”

We at Irritecnica always try to advise our customers on the best products for the construction of the lifting system, starting from the pump which represents the heart of the system, passing through the electrical panel which can instead be compared to the brain and finally the pipes, which constitute the arteries of the entire system.

The correct choice of the pipes is undoubtedly of fundamental importance to ensure efficiency, correct performance and durability of the entire system. Despite this, in recent times we have been seeing a general trend of reducing the construction costs of lifting systems which leads to the choice of pipes that are not fit for the purpose, mainly made of plastic materials, which although initially cheaper, involve a greater economic outlay in the long run for the customer.

Water lifting is a particular field of application, in which the pipes are subjected to high pressures and torsional and traction forces which impose high standards of performance and efficiency.

Plastic pipelines

The tendency to increasingly reduce production costs has led over the years to the use of plastic materials also for the delivery pipes of the water lifting system, where the use of steel was widely used and therefore was dominant.

The first plastic pipelines that became widespread in recent years were those made of polyethylene, which were easy to produce and affordable. In installations with polyethylene pipes, the pump is supported by a nylon rope, to prevent the full weight of the pump and the water column from weighing on the pipe.

However, polyethylene pipes are not very resistant to traction and high pressures and also cause the pump to operate off-axis, resulting in greater wear of all system components and their premature failure over time.

Over the time, manufacturers have begun to introduce increasingly innovative plastic pipes, which have in a certain sense mitigated the problems encountered with polyethylene. An example of this are uPVC pipes, much sponsored in this period by manufacturers, certainly more resistant to traction than polyethylene pipes and capable of withstanding higher pressures, equipped with anti-unscrewing mechanisms and increased thickness (only for some models called “super heavy”).

Plastic is certainly cheaper than steel, even more so than stainless steel, so manufacturers and even installers have begun to sponsor this solution, which certainly has advantages also from a technical point of view, such as in transport of drinking water, not possible with carbon steel pipes.

However, the reality is very different and the advantages stop here.

Most of the advantages are those of low production costs which allow manufacturers to increase their revenues and which is reflected in a saving also seen by the customer, even if in a smaller proportion. However, a lower initial cost does not mean a lower cost for the entire operating life of that system.

Although uPVC pipes have increased in quality and performance over the years, they still remain a plastic material subjected to strong stresses and mechanical forces, and this can translate into early breakages of the pipe and consequent greater financial outlays by the customer compared to the case where he/she had invested more in steel pipes.

“The initial savings game is not worth the candle!”

For example, several of our customers who opted for uPVC plastic pipes then had to experience unexpected breakages, typically due to strong torsional forces or poor quality of materials. We can report the case of a customers where, despite an initial saving of 18% by choosing a “super heavy” uPVC pipe instead of AISI 304 stainless steel, after 5 years the pipe broke down (see the photo) and he had to sustain the costs of recovering the pump from the well and renovating the entire system (with the exception of the electrical panel), with an economic outlay 200% higher than the initial one. We realize that the initial savings game is not worth the candle!

Steel flanged pipes

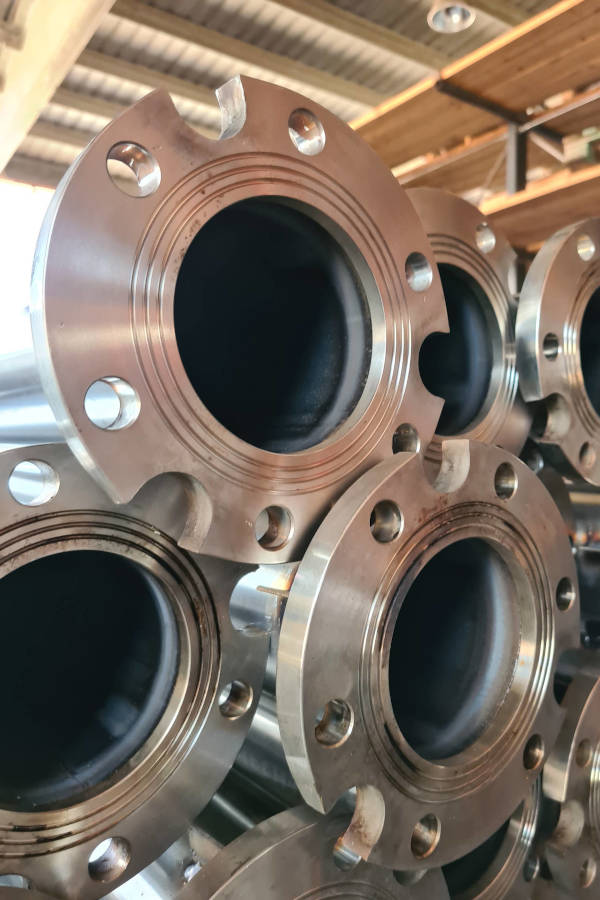

Steel has always been the material par excellence in the construction of delivery pipes for lifting systems. Used a lot in the past as there were no alternatives, we at Irritecnica continue to offer it to our customers instead of plastic pipes for the reasons abovementioned (with the exception of some particular cases).

The flanged steel pipes, thanks to the use of the flange as a coupling method between the pipes and the interposition of a gasket between them, have a very strong pressure resistance, which allows them to be installed even at great depths.

Furthermore, being made of steel, the flanged pipes optimally withstand the torsional force due to the switching on of the electric pump, in addition to the fact that they are resistant to the traction exerted by the weight of the electric pump, to the vibrations produced during its operation and to water hammer that are created following the shutdown.

Also, the aspect of eco-sustainability should not be underestimated. Compared to pipes made with plastic materials, flanged pipes are eco-sustainable and have a low environmental impact. By using flanged pipes you do nature a favor, avoiding both the dispersion of microplastics, which can spread during the normal transport of liquids in deteriorated pipes, or their abandonment in the environment once they reach the end of their life, if not correctly disposed of or recycled.

To learn more about all the aspects related to the advantages that galvanized steel or stainless steel flanged pipes can have for the use in water lifting systems and in general for different applications, consult the dedicated page that we have prepared at this link.

Irritecnica produces and sells different types of flanged pipes for submersible electric pumps and vertical axis pumps. The pipes can be made of carbon steel or AISI 304 or 316 stainless steel and have standard diameters, thicknesses and lengths, however customizations are made upon customer request. For further information, consult our company website Irritecnica.it or our thematic sites dedicated to flanged pipes Tubiflangiati.it and Flangedpipes.com.